factorio

My Factorio Logistic Train Evolution, Part 1

I’m in love with this game. Factorio is a rare gem that allows you to sink 1,000 hours into building factories, circuits, and trains and still be learning something new. I’m on my third map now, and each one has been an amazing learning experience.

The most advanced circuits I’ve created so far have been for vanilla logistic train loaders, which supply all my wall defense, outpost, and other remote building needs.

Since I began playing in March 2020, I’ve saved a daily snapshot of my factories, which I can now dig through to describe the evolution of my train logistic systems.

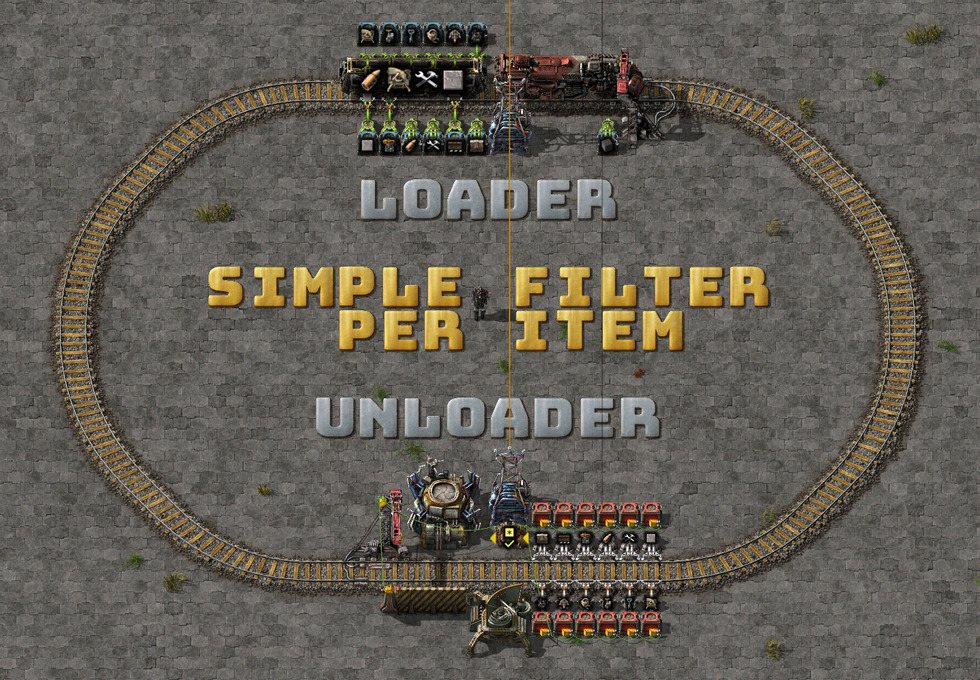

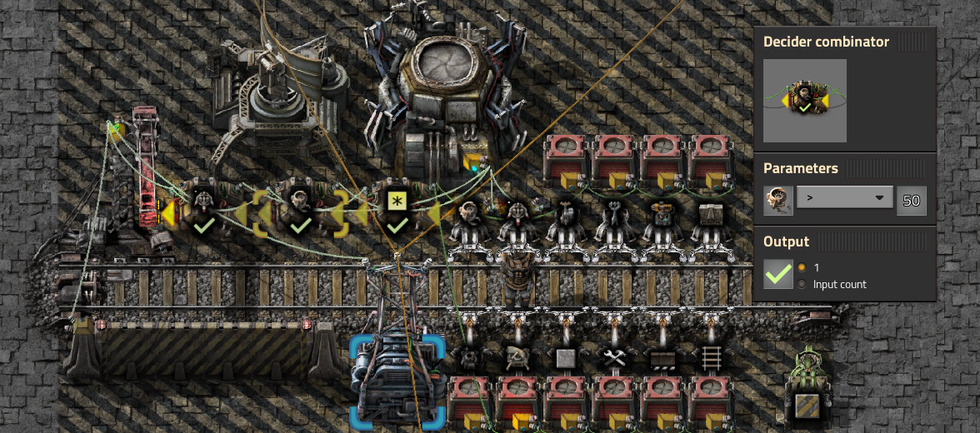

There’s a natural progression between the systems, going from the simplest designs using per-item filter inserters:

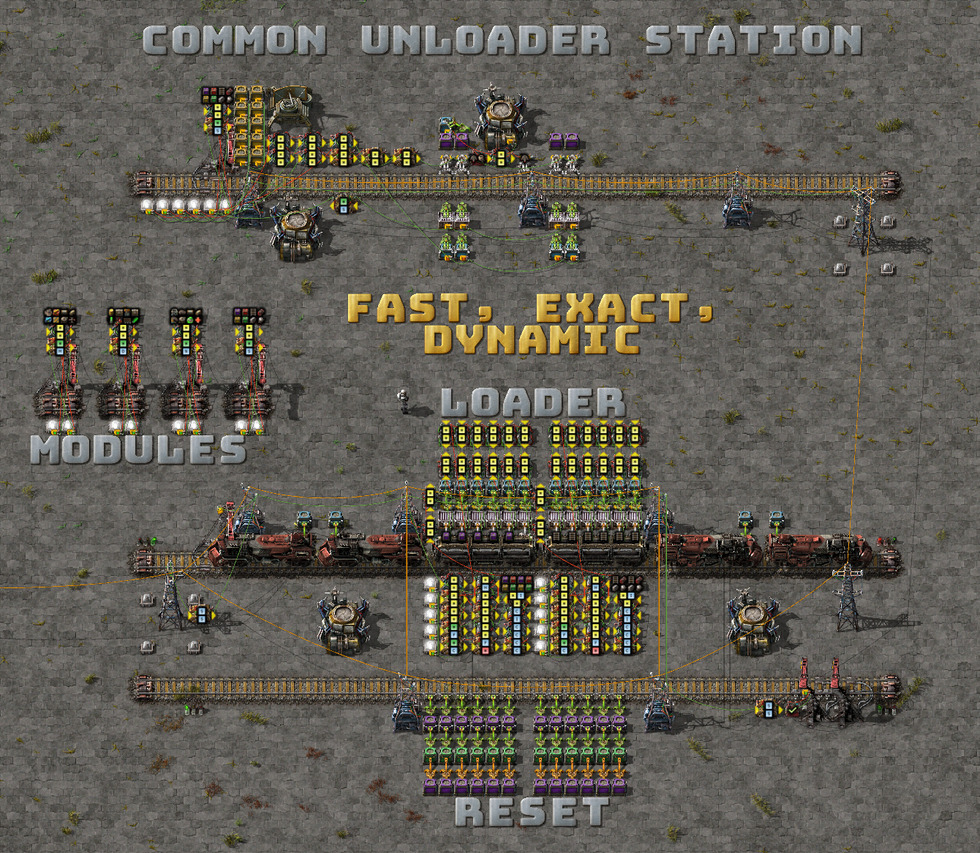

To a module-based, fast, and exact logistic loader/unloader system:

In this series of posts, I’ll walk you through how I got there and the problems I encountered along the way.

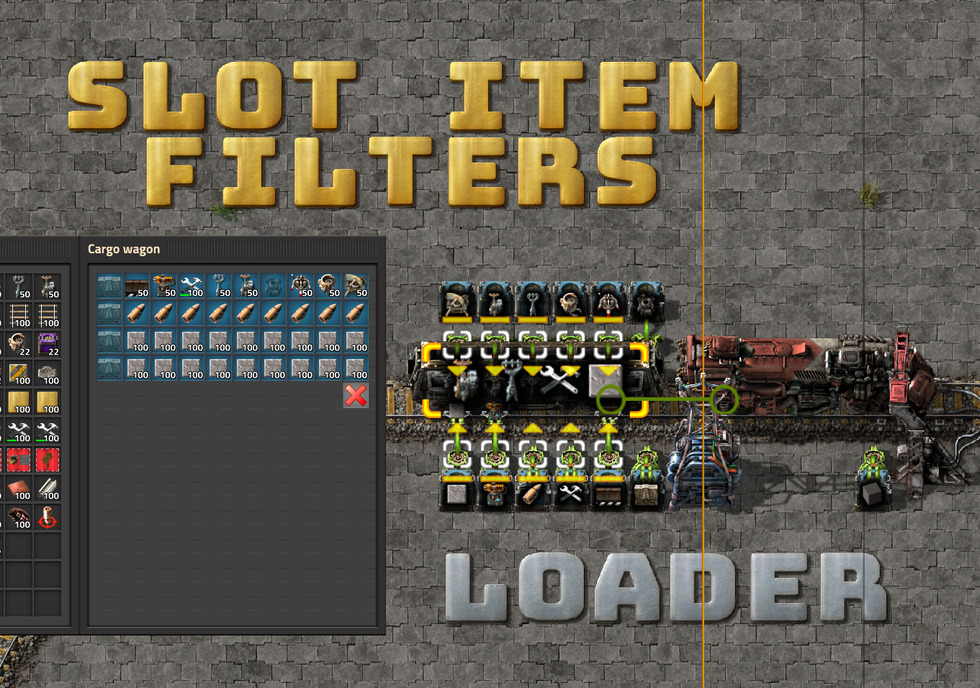

Simple: reserved wagon slots

Middle-click on each cargo wagon slot to filter it to a specific item. I used this to create several trains for different purposes:

- Wall/defense supplies: ammo, walls, lasers

- Build train: inserters, chests, power poles, etc.

- Solar train: solar panels, accumulators, etc.

I set the schedule to Full Cargo and had the trains wait for an outpost to enable itself when it was short on supplies.

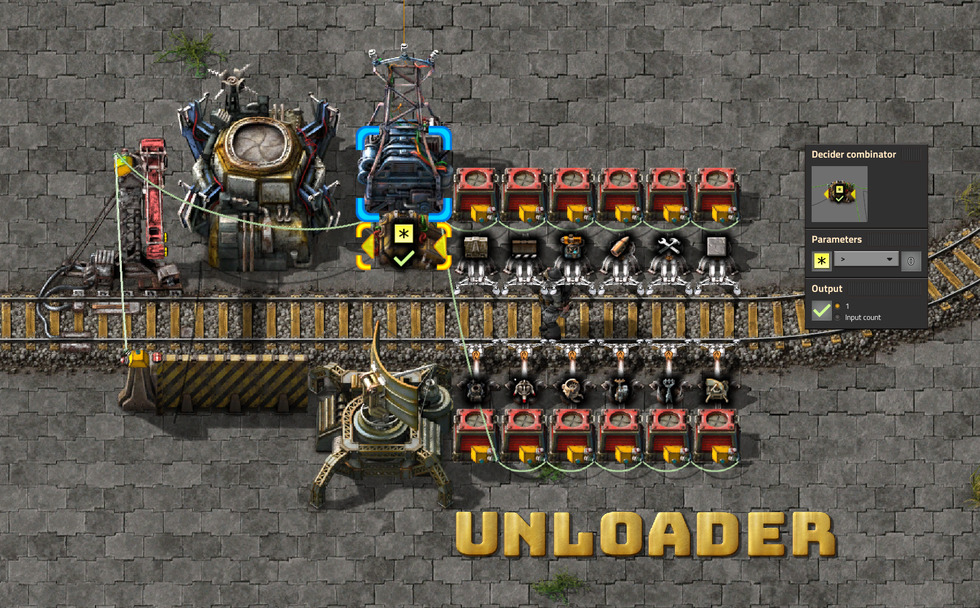

The unloader is the inverse of the loader: filter inserters remove only specific items into space-restricted provider chests.

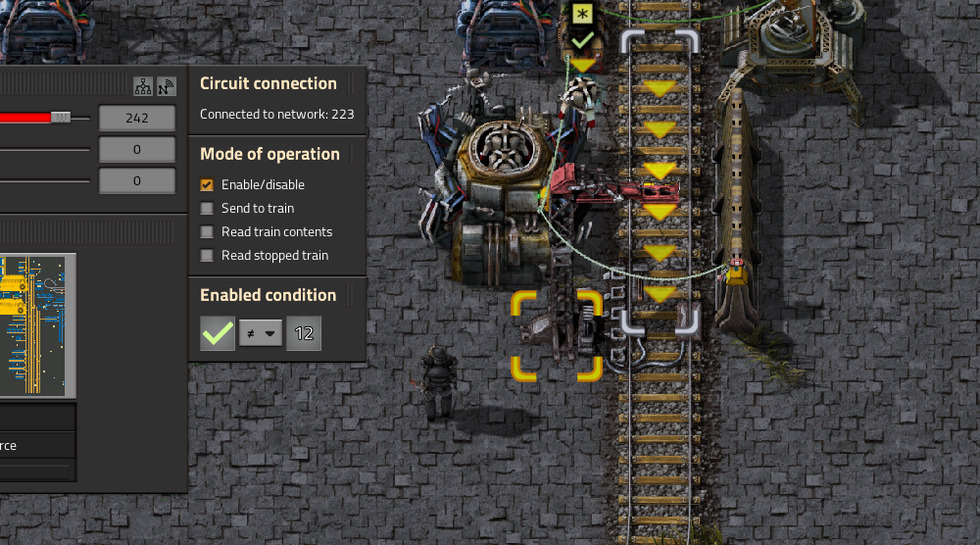

The circuit above counts the number of unique items in the chest. I wired this to the train stop to enable it when [tick] != 12:

The departure condition should be Inactivity, which may depend on your bot speed. I used between 5 and 10 seconds almost everywhere.

Pros

Simplicity and compactness are the big wins here. You can also add more cargo wagons to transport more item types (24, 36, etc.) or more of each item.

Cons

Adding that 13th item..

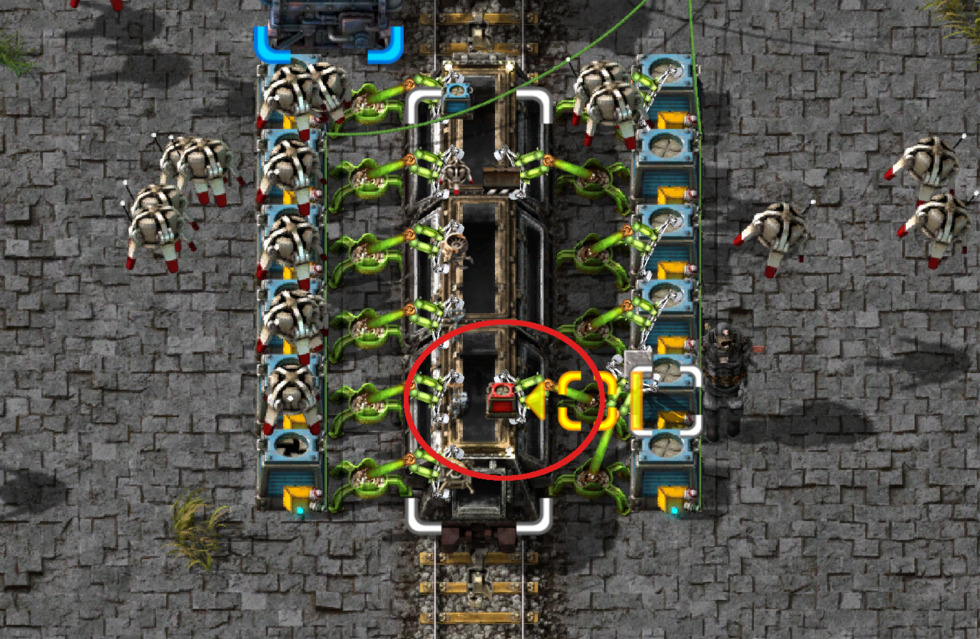

A dead-end I hit when trying to extend this system beyond 12 items per wagon was the stuck inserter. In this requester chest, I configured passive provider chests and lasers. Unless the inserter’s hand completely empties into the wagon, it will stall and never insert the other item types:

Micromanaging inserter stack sizes is a recurring theme with more complex logistic circuits.

It’s best to use additional wagons for more items with this design.

Train requester gate

You can add a wall and a gate to detect the player. Make the wall-gate connection output tick: 1 to activate the tick != 12 condition, and the train will be dispatched to pick you up!

Trash wagon

A simple addition to this setup is a separate wagon for returning waste (rocks, trees, deconstruction debris) to base for use or disposal.

Direct robo-insertion

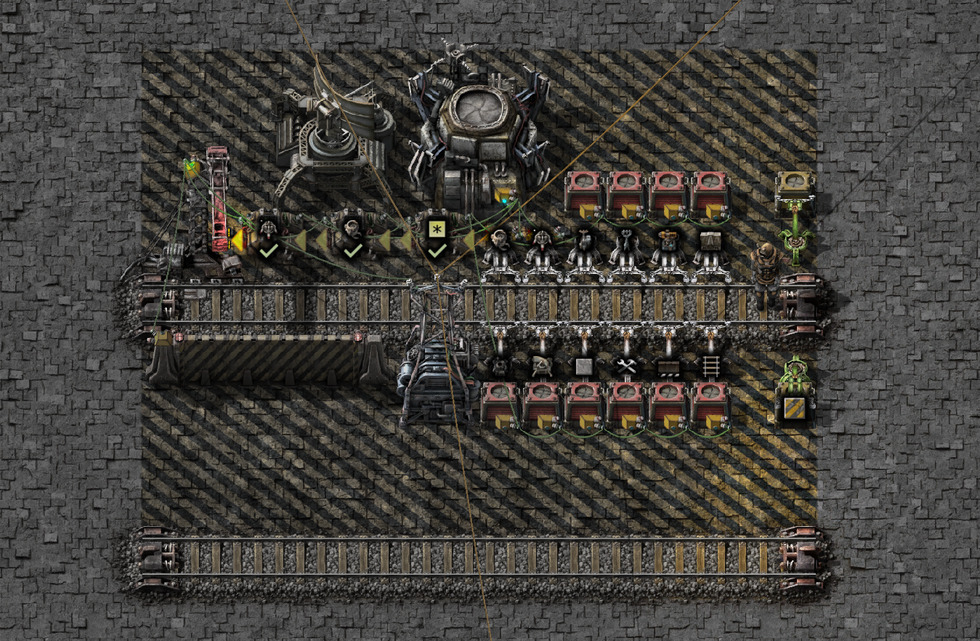

A pain point when setting up a new logistic unloader outpost was having to insert the initial logistic bots manually. Like chests, you can insert bots directly into a roboport from a cargo wagon. I replaced the first two passive provider chests with the corner of the roboport.

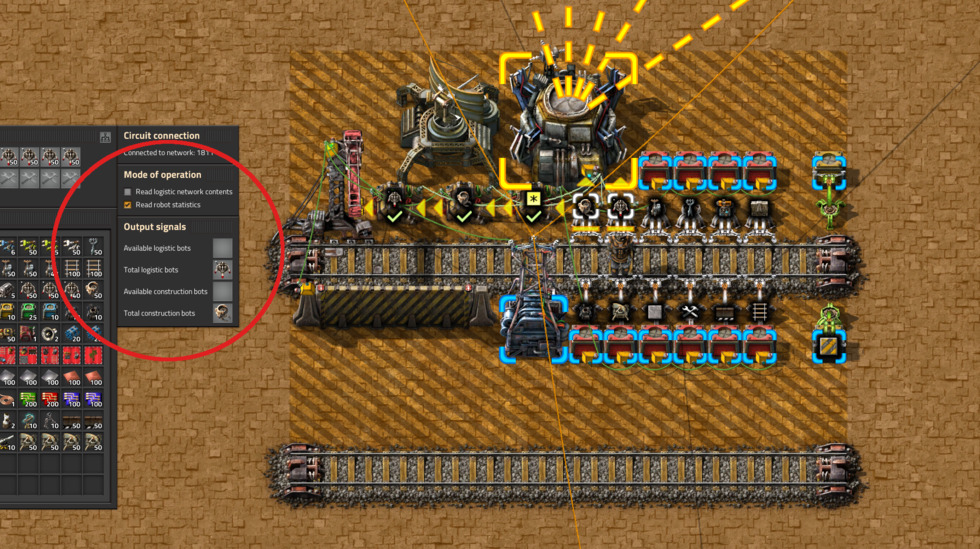

A circuit connection to the roboport lets you inspect bot stats and conditionally enable the inserter up to a desired threshold (e.g., logistic bots < 100).

After a while, I noticed a problem: waves of biter attacks were burning through my bots. I needed a way to monitor my bot levels and request a stock-up when they reached critical levels. Enter the two additional decider combinators on the left. Both are wired to the roboport to check the bot stats, and both will output tick: 1 when their conditions are true (construction bots > 50 and logistic bots > 50).

No changes to the train stop’s tick != 12 condition are needed. The train station will be automatically disabled when:

construction bots > 50logistic bots > 50- The number of unique items in the chests is

10

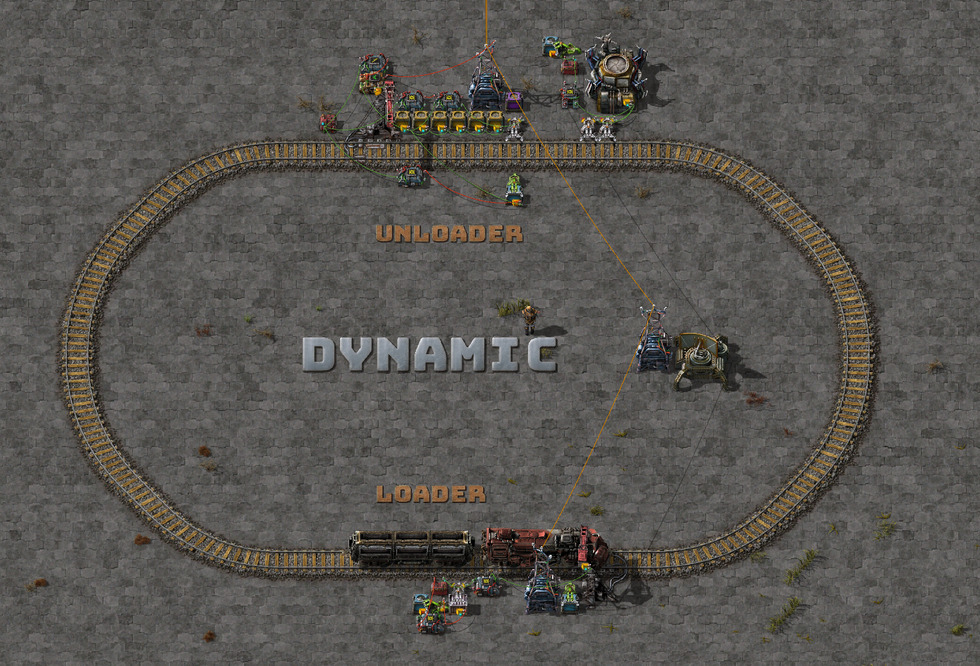

Train stacker

I was reaching the throughput capacity of a single train and decided to add more. Simple, right?

Multiple trains, dynamic stops & no-pathing nightmares

Multiple trains and dynamic train stops are a recipe for disaster. I found that the first train to reach an outpost would deactivate the train stop, causing other en-route trains to no-path in the middle of critical intersections and stalling my entire train network. I had incorrectly assumed that if there were no active train stops, a train would automatically skip to the next stop in its schedule and return to base.

A trick I missed in my first factory was to use a modular rail blueprint with red and green wires included on the power poles. I didn’t know this at the time, but circuit connections in blueprints are free, so there’s no additional cost to including them everywhere.

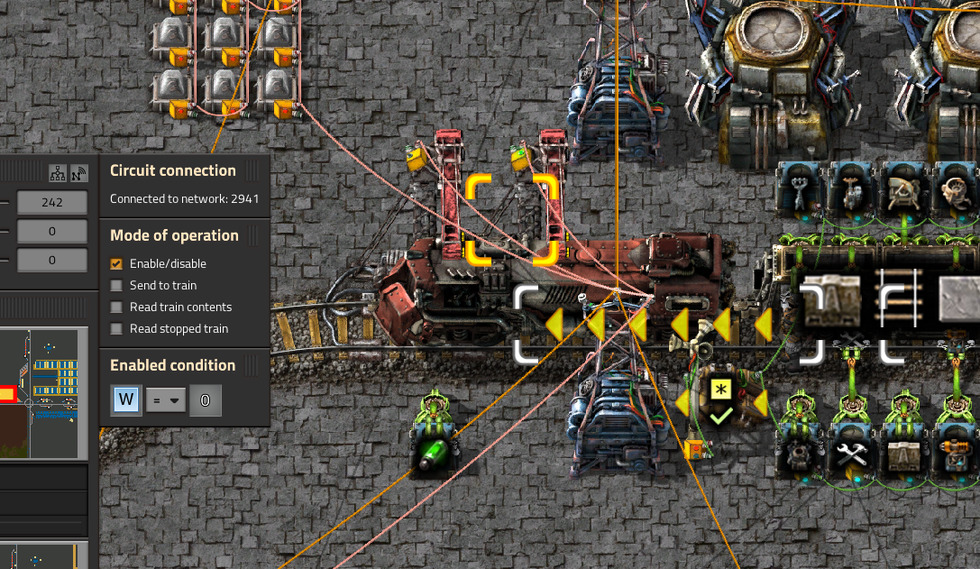

The rail circuit network can be used to request trains and provide a “home” for orphaned trains when all other stations are disabled.

The no-pathing trains drove me up the wall. Despite the urge to go all Office Space on my save file, I walked my rail network and added a red wire. This was no small task:

Then, I changed the outpost station to send a signal on the rail network when it needs a train (e.g., W: 1 for the wall resupply train). I also changed the train stop to check for that signal locally and enable/disable the stop in sync with the request signal (W == 1). I made sure to use a different color wire for the train stop and the rail network so that all stations didn’t enable when any one of them did.

Finally, I set up a dummy station back at base to activate only when there were no train requests (W == 0).

I also changed the loading train’s schedule to leave the station only when a train is requested (W > 0); otherwise, the train(s) will loop through the dummy station endlessly.

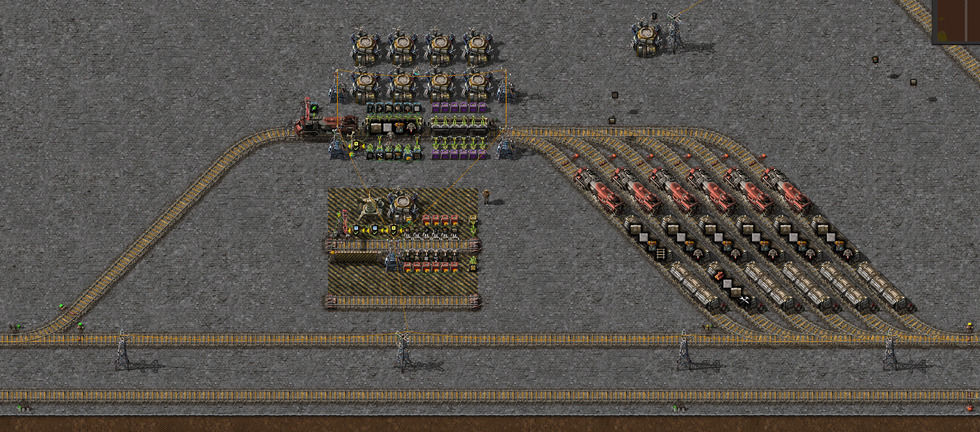

Quantum leap #1: dynamic logistic loader/unloader stations

The magic here is that the logistic request is set via constant combinators at the loader and unloader stations. The item request signals are crunched by circuits at both ends to load and unload the trains with filter inserters in set-filters mode.

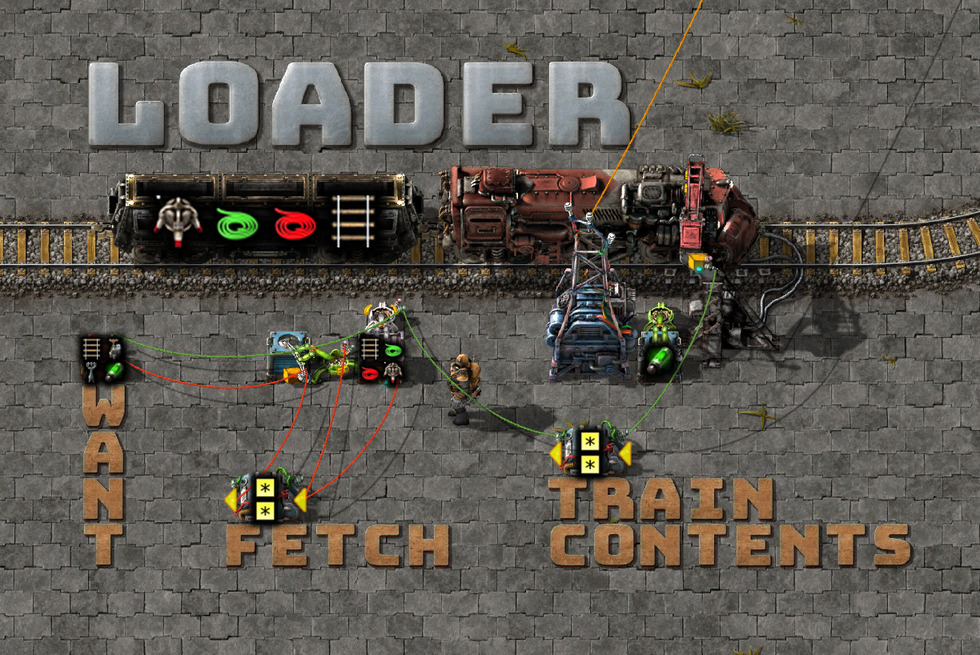

Train loader

The loader has three components. I use the WANT combinator to set the train’s contents, the FETCH circuit to pre-cache the storage chest with the requested items, and the TRAIN CONTENTS circuit to subtract items from the filter inserter’s set-filters signal as the train is filling up. The train stop must be set to read the train’s contents.

The FETCH circuit requires a requester and a storage chest because you can’t both set requests and read a chest’s contents at the same time (due to game mechanics). Further, the inserter is set to read its hand contents (in Hold mode), which is joined with the storage chest’s signal and subtracted from the requester chest’s set-requests signal.

As with the previous iteration, the train schedule will only allow a departure if the circuit network requests a train. Don’t forget to connect the train stop to the rail circuit network (like I did in this screenshot!).

Aside: the Picker Dollies mod is a game changer for designing and debugging circuits. You can move the components around and rotate them without losing your wire connections.

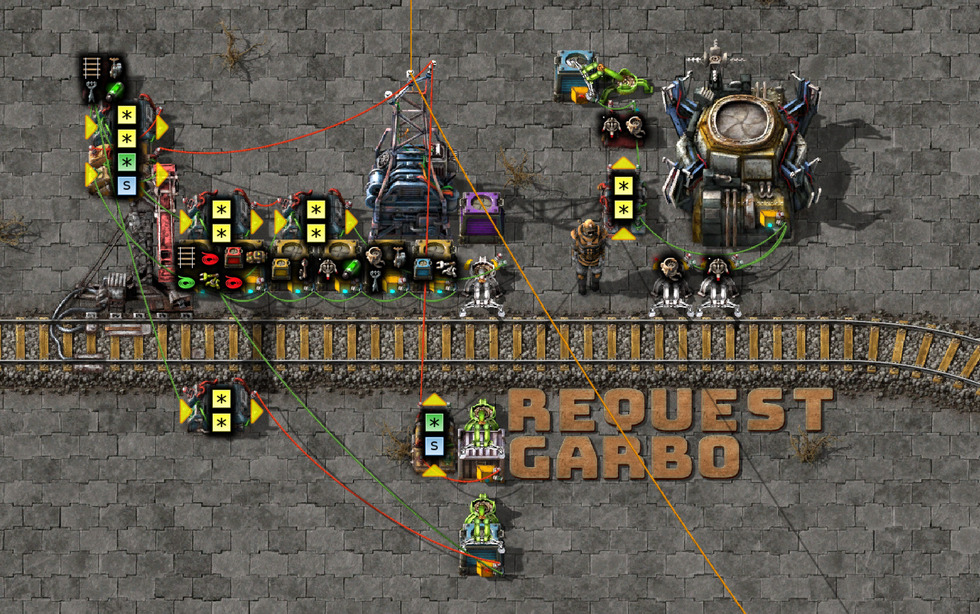

Train unloader

The unloader has many more components.

The BOTS circuit has an upgrade. To bootstrap the system, bots are inserted directly from the cargo wagon up to the thresholds set in the filter inserters (logistic bots < 50, construction bots < 50). Additional bots are inserted via the requester chest up to the thresholds set in the constant combinator (based on the outpost’s needs). The bot stats are subtracted from the requester chest’s set-requests signal.

I like this system because I can replenish bots from or discard bots to the outpost’s logistic storage. If needed, those bots can be inserted into the bot network or returned to base.

The REQUEST circuit takes the WANT signal and checks if we have at least 50% of those items in logistic storage ([*each] / -2), which is then added to the logistic storage contents (the storage chest’s green wire). The decider combinator checks if any stock is below zero ([*anything] < 0) and, if so, enables the train stop and emits a signal for this station (S: 1) onto the rail circuit network.

The UNLOAD circuit subtracts the WANT signal from the storage circuit and inverts the result. Any positive item values activate the filter inserter in set-filters mode. I made a rookie mistake in the first version of this station by using the logistic network’s contents signal from the roboport instead of the signal from explicit storage chests. You can guess what happened at my smelting outposts.

TRASH subtracts 200% of the WANT signal from the storage chests. Any positive values are requested by the requester chest in set-filters mode to be dumped into the next cargo wagon that visits the station.

Trash train request

With a layer of indirection in the trash system’s chests, we can detect whether there are any items to send back to base and request a pickup. I frequently change this to request a train only when there are at least 100 items to return to base. Customize it to your needs.

Pros

Pros: No more fiddling with cargo wagon filters and keeping slot filters in sync across multiple trains. Changing a combinator at the loader and unloader is all that’s required. You can do both remotely by dropping a blueprint of the new combinator over the old one.

You can have up to 40 item types per wagon and 80 if you duplicate these circuits for each wagon.

Cons

Cons: Inexact insertion amounts

The stack inserter (if upgraded) will insert 12 items at a time. All vanilla item stack sizes are not a multiple of 12. To compensate, I rounded down most amounts to the nearest multiple of 12. Otherwise, items with a stack size of 50 (inserters, chests, etc.) would each occupy two slots, halving the number of item types I can transport per train.

I’m really impressed with the vanilla game balance here; this forces you to evaluate the pragmatic trade-offs between the additional time and complexity required to solve the problem “correctly.”

Speed

Gosh, this is slow. Dog-slow. Watching a single inserter trash 4,000 trees or take out 2,000 rails is slower than watching paint dry.

A naive, rough workaround is to add another row of chests and inserters to the existing circuits:

But this has its problems as well: over-insertion in the wagon, over-removal of items into the outpost, and over-trashing items in the trash circuit. Most of these are solved in later circuits, so read on.

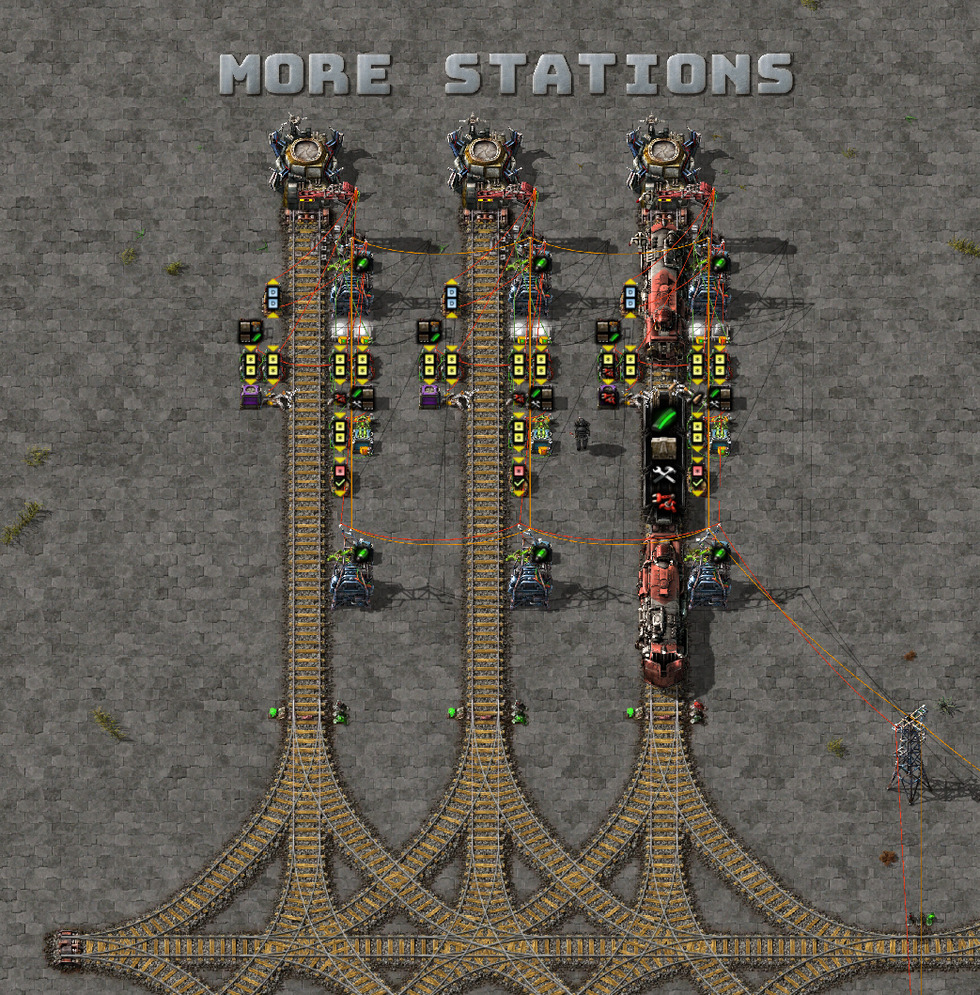

Another solution I explored was to have more logistic loading stations:

This was also problematic due to the thundering herd of trains that would be released whenever an outpost train stop was activated. A 30-second train load time and a single loading station do have their benefits.

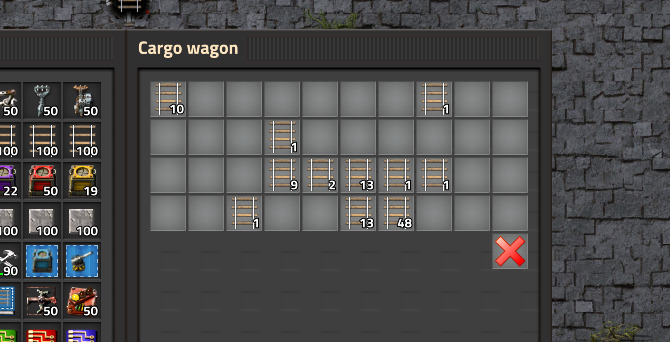

Cargo wagon fragmentation

Successive loads and unloads of the cargo wagon may only partially remove items. When the train returns to the station, those items may be put into different cargo slots (especially if there’s trash to be removed from the wagon at the same time and slots are freed up during loading).

Case in point: this reads as rail: 100, but it will mess with the cargo/slot utilization (or “goodput”) of the wagon:

Furthermore, you have no way of inspecting the fragmentation state. The only solution for this is a reset/trash stop in the train’s schedule to reset the wagon(s) to a known-good state (empty).

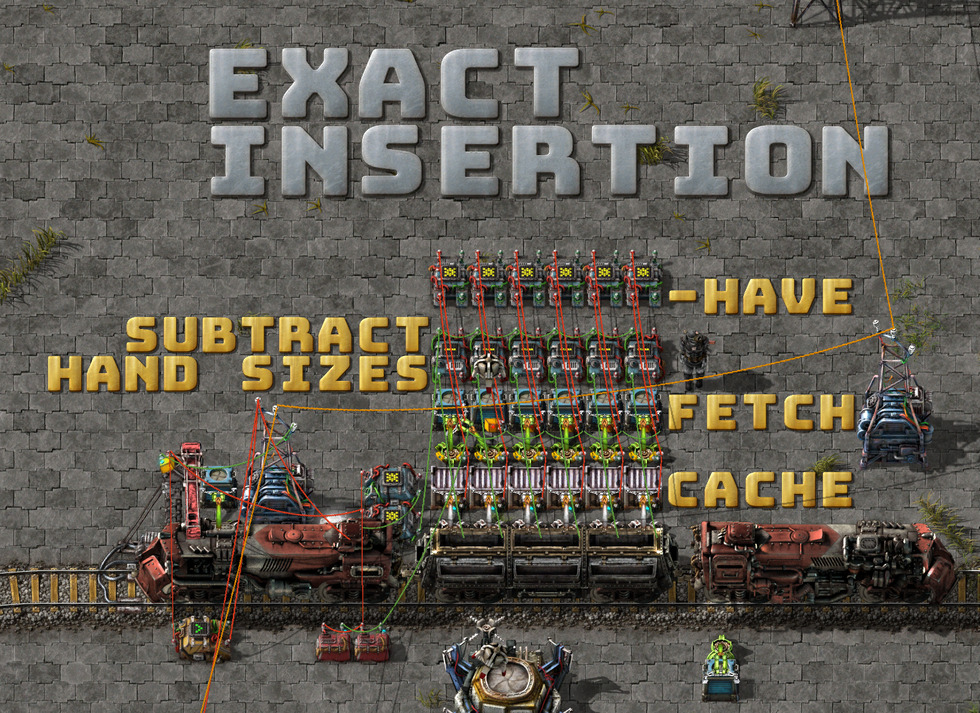

Quantum leap #2: Exact item insertion

The FETCH, CACHE, and -HAVE lines are repeats of the prior pre-cache circuits. I’ll explain the SUBTRACT HAND SIZES configuration below.

The magic here is that we can set the hand size per swing for each of the filter inserters. With a mix of hand sizes, we can selectively enable/disable each to insert exact amounts.

Let’s step through an example. We have a signal, rail: 100, which is the difference between what we want and what we have in the cargo wagon.

A common hand-size configuration I used is [1, 3, 12, 12, 12, 12], which will insert rail: 100 in four swings.

Let’s step through this with a bit of code:

print('Column, Hand Size, Cumulative stack size, Enable threshold')

print('------, ---------, ---------------------, ----------------')

sizes = [1, 3, 12, 12, 12, 12]

for i in range(len(sizes)):

cum_size = sum(sizes[0:i+1])

print(i+1, ',', sizes[i], ',', cum_size, ',', cum_size-1)

print()

print('Swing, Hand size, Remainder')

print('-----, ---------, ---------')

signal = 100

swing = 0

while signal > 0:

swing += 1

for arm in sizes:

if arm > signal:

continue

signal -= arm

print(swing, ',', arm, ',', signal)

$ python hands.py | column -t -s ',' -L

Column Hand Size Cumulative stack size Enable threshold

------ --------- --------------------- ----------------

1 1 1 0

2 3 4 3

3 12 16 15

4 12 28 27

5 12 40 39

6 12 52 51

Swing Hand size Remainder

----- --------- ---------

1 1 99

1 3 96

1 12 84

1 12 72

1 12 60

1 12 48

2 1 47

2 3 44

2 12 32

2 12 20

2 12 8

3 1 7

3 3 4

4 1 3

4 3 0

The ‘Enable threshold’ column is what’s inserted into the SUBTRACT HAND SIZES row of arithmetic combinators, with the expression [*each] - $x.

Here, we can see a perfect example of a wagon load:

Cons

Cons: Slower loading times due to static hand sizes. You must trade throughput for precision. There are still improvements to be made here, so read on.

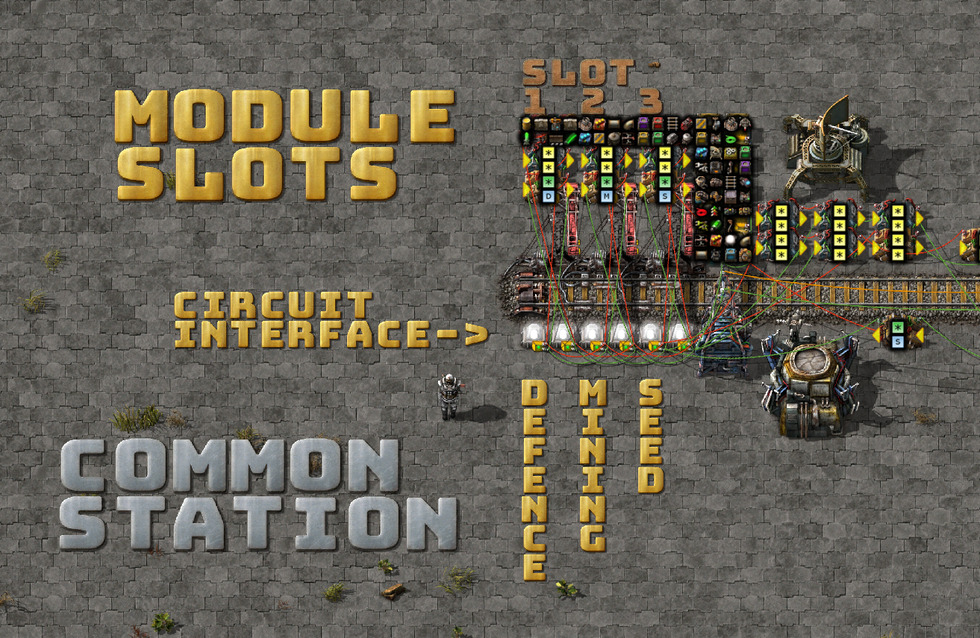

Quantum leap #3: Module slots!

This concept was first mentioned to me by a friend, who was describing https://github.com/rain9441/factorio-tls. I still haven’t looked at these templates in-depth because I enjoy building and discovering these things for myself. The module concept was easily adapted to my stations. I’ll be sure to check them out when I think I’ve hit the ceiling of my current design.

Now that we have generic loader and unloader circuits, the only difference between specialized stations (for common items, mining items, defense, nuclear, etc.) is the constant combinator that sets the item requests.

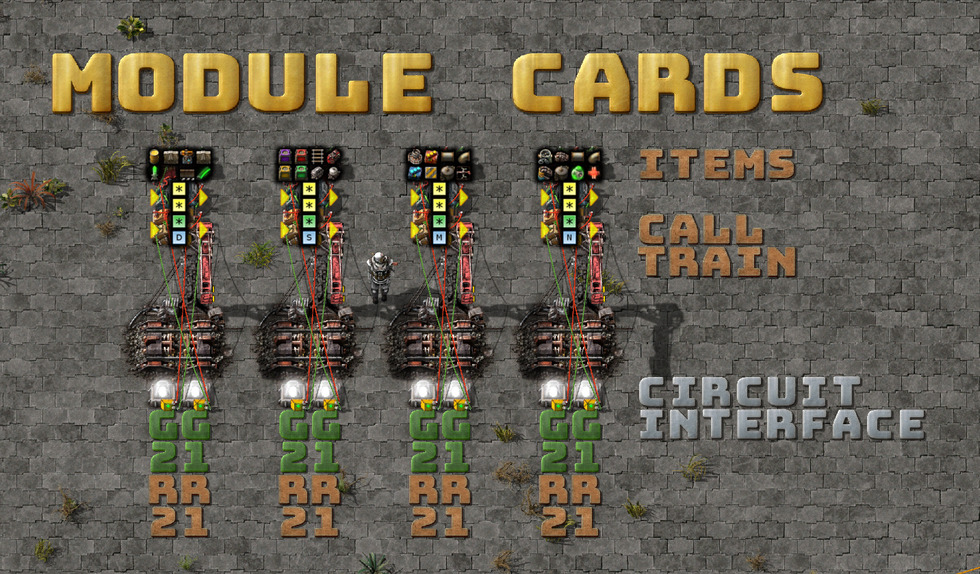

I extended the unloader station to support multiple “module cards” that add their combinator contents to the outpost’s unloader/stock-level circuits. Each will know how to request specialized trains to restock [D]efense, [M]ining, [N]uclear, and [S]eed.

The innovation here is the ability to drop a module into any of the three slots and have it remain connected to four separate circuit networks:

- Red 1: The sum of all item requests.

- Red 2: The current train contents.

- Green 1: The logistic storage.

- Green 2: The public train request network.

The row of lights at the CIRCUIT INTERFACE alternates between two red and two green circuits, which act as an interface between the module cards and the logistic unloader station. This allows the module cards to be as small as possible and their circuit connections to be self-contained:

Pros

Pros: Common outpost station, modular item requests. Fast loading due to the use of multiple trains for requests.

Cons

Cons: Due to the size of the train stop (2 tiles wide) and the wagon size (6 tiles), a natural limit to this design is three module slots per station (without adding padding tiles or additional locomotives). I’ve been creating more specialized trains when I hit this limit. Don’t forget that you can replace or remove cards to return items to base.

You should be careful when adding multiple outpost stations within the same bot network, due to the use of explicit storage chests for logistic storage. If there are multiple, disjoint sets of logistic storage, unload conditions may never be satisfied. Joining them is the simplest solution, but you could also use logistic network stats from the roboport (though this has its own problems if your outpost produces items).

Speed: It’s still possible to improve the speed further by splitting the trash circuit and inserters into a separate train stop.

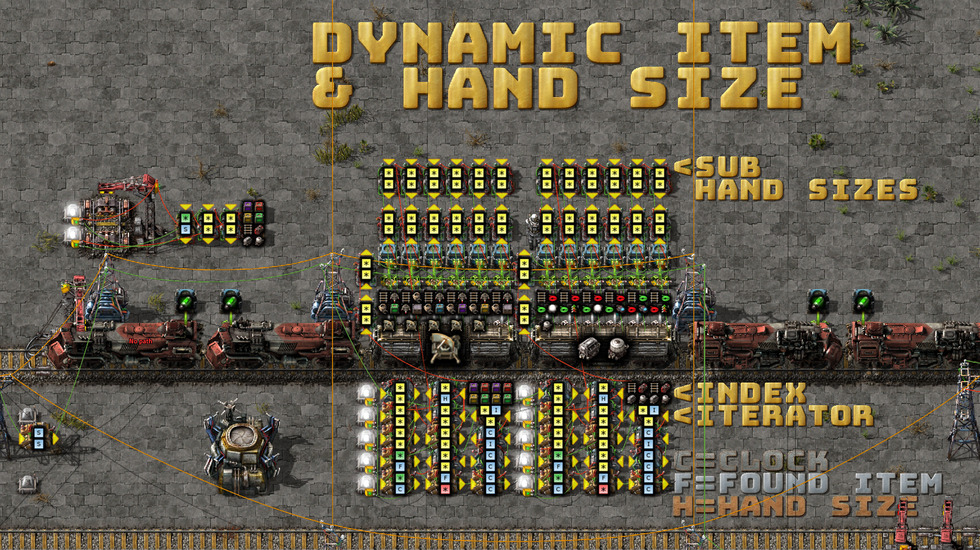

Quantum leap #4: Dynamic items and inserter stack sizes

A limitation of the previous loader is the complex, messy, and static inserter stack sizes required to insert odd amounts exactly.

The problem (until now) was that I had no way of taking a mixed-item signal like { rail: 12, chest: 7, fuel: 1 } and setting both the correct item and stack sizes for each.

Life would be a lot simpler if inserters supported [*each] in the hand-size signal, which would set the hand size to the item’s value.

It took weeks, but I found a solution using an index, an iterator, and a clock circuit.

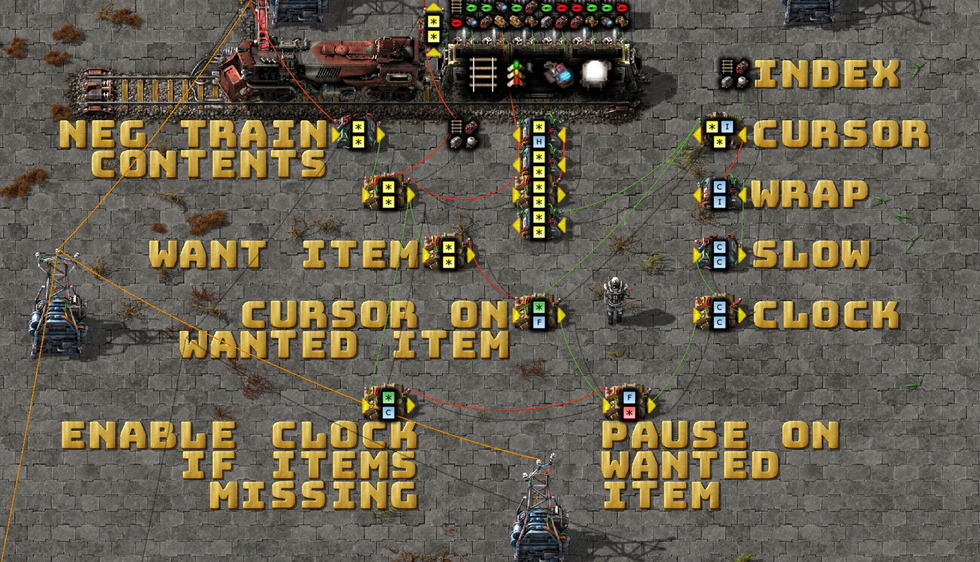

Let’s explode this circuit and see what’s going on:

The NEG TRAIN CONTENTS and the constant combinator are familiar elements from previous circuits. This subtracts what’s in the train from what I want. To make the output easier to view, I then filter with [*each] > 0, but this might not be necessary.

The WANT ITEM combinator turns a mixed signal of what’s missing ({ rail: 100, chest: 50, ... }) into { rail: 1, chest: 1, ... } for each item. This allows me to do a set union ([*anything] == 2) in the CURSOR ON WANTED ITEM decider combinator with the current CURSOR item. If there’s a match, the clock signal is disabled in the PAUSE ON WANTED ITEM combinator ([F] == 0 -> [*anything]).

The ENABLE CLOCK IF ITEMS MISSING combinator could be replaced by a constant combinator and a constantly running clock, but I might find it useful to feed the “done” signal into the train schedule at some point. Plus, the circuit noises are annoying when it’s idle.

The CLOCK is a counter and a memory circuit in one (a clock). If the clock signal is enabled in ENABLE CLOCK IF ITEMS MISSING and isn’t paused by PAUSE ON WANTED ITEM, then the clock will count up by 1 per game tick.

The SLOW arithmetic combinator slows the clock down to match the circuit’s delay. Many calculations are required to determine the cursor item, whether there are missing items, if the cursor matches a missing item, and so on. If there were no delay, the clock would be long past the items of interest before the pause signal had time to activate. At present, this is set to divide the clock signal by 6. Improvements to this circuit, if possible, may be able to lower this to 5.

The WRAP combinator takes the slower clock signal and wraps it around the max item index (18 items per constant combinator; the expression is C % 19 -> I, which you can increase if necessary).

The CURSOR combinator compares the index signal to the wrapped, slowed clock signal and will only output the matching item: [*each] == I -> [*each] 1.

The INDEX is a constant combinator that includes the same item types as the request combinator but numbered 1..n for each item type. Gaps are allowed (but are wasteful).

With what has been covered so far, we can now take a signal like { rail: 100, chest: 50, fuel: 10 } and isolate it to one item for processing at a time (e.g., rail: 1). Notice that we don’t have the quantity information here yet.

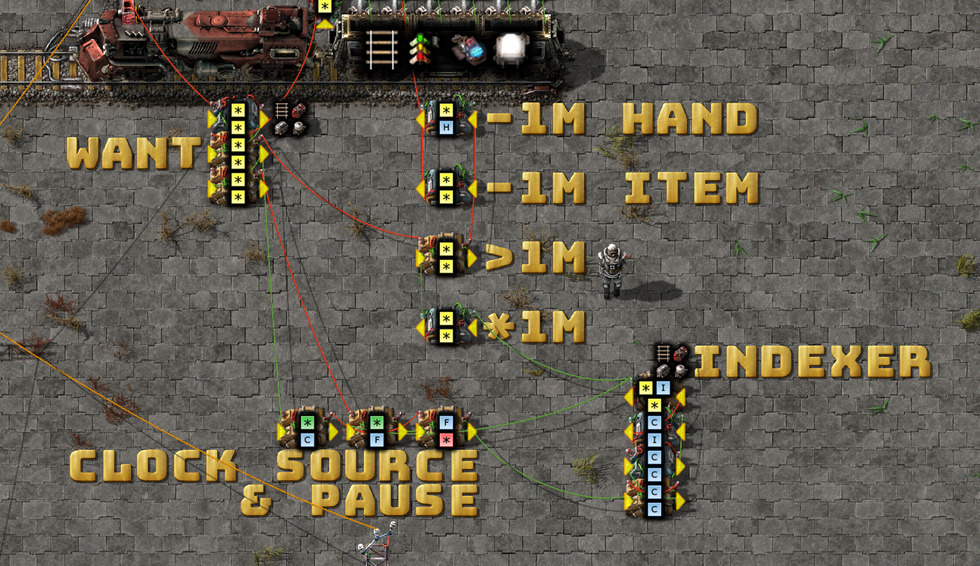

We use this part of the circuit to produce the item and hand signals, which are fed into the wagon’s inserter array.

To rejoin the quantity information with the cursor signal, I do a simple multiplication-and-subtraction trick.

Multiply the INDEXER signal by 1,000,000:

{ rail: 1 } * 1,000,000 -> { rail: 1,000,000 }

Then, sum with the WANT signal:

{ rail: 1,000,000 } + { rail: 100, chest: 50, fuel: 10 } -> { rail: 1,000,100, chest: 50, fuel: 10 }

And filter for values above 1,000,000:

[*each] > 1_000_000 -> [*each]

Which results in rail: 1,000,100. Then, subtract 1,000,000 to re-normalize the value:

[*each] - 1_000_000 -> [*each]

This gives us a final value of rail: 100. Woohoo!

That final calculation is duplicated to produce the hand signal as well:

[*each] - 1_000_000 -> H

Both together produce the perfect signal for our inserters—{ rail: 100, H: 100 }—for each item at a time.

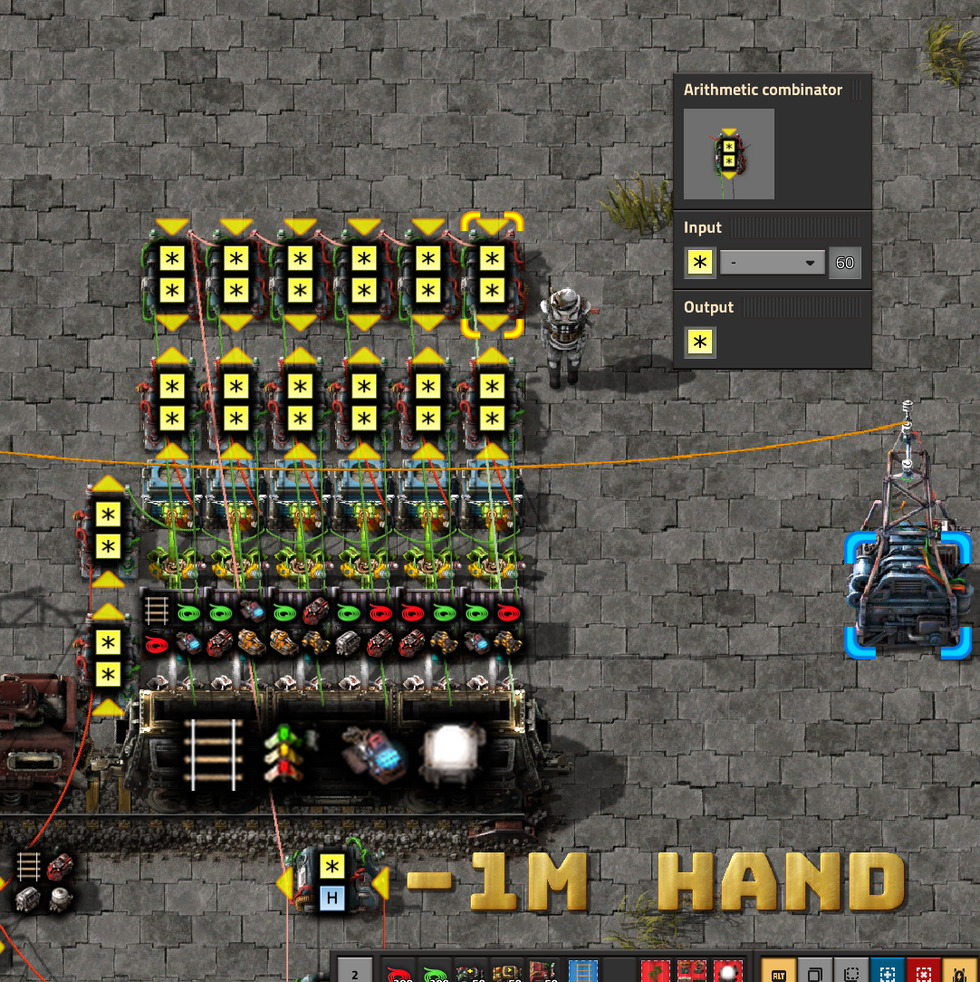

The cumulative hand-size subtractions are now simplified to multiples of 12 ([0, 12, 24, 36, 48, 60]) and are subtracted from both the item and hand signals.

The swings for rail: 100 look like this:

item_signal = 100

hand_signal = 100

num_inserters = 6

swing = 0

print("Swing, Hand Size, Item Signal, Hand Signal")

print("-----, ---------, -----------, -----------")

while item_signal > 0:

swing += 1

for _ in range(num_inserters):

hand_size = min(hand_signal, 12)

if hand_size > 0:

item_signal -= hand_size

hand_signal -= hand_size

print(swing, ',', hand_size, ',', item_signal, ',', hand_signal)

$ python rail_hand_example.py | column -t -s ',' -L

Swing Hand Size Item Signal Hand Signal

----- --------- ----------- -----------

1 12 88 88

1 12 76 76

1 12 64 64

1 12 52 52

1 12 40 40

1 12 28 28

2 12 16 16

2 12 4 4

2 4 0 0

Remember our prior attempt?

Swing Hand size Remainder

----- --------- ---------

1 1 99

1 3 96

1 12 84

1 12 72

1 12 60

1 12 48

2 1 47

2 3 44

2 12 32

2 12 20

2 12 8

3 1 7

3 3 4

4 1 3

4 3 0

Thats all for now!

I’ve been writing for four days now and need some time to experiment with several ideas I’ve had while writing this guide.

If there’s interest, I’ll follow up with my results.

I still have a long bucket list of features to add and quirks to remove:

- Faster loading/unloading.

- Simpler index configuration.

- Balancing items across wagons automatically.

- Separate trash trains.

Blueprints

Here’s a copy of the final blueprint book: 2020-05-22-blueprint.txt

Others are available on request (after a bit of cleanup).

Contact

I’d love to hear your feedback, corrections, contributions, and fixes!

Email: mason.larobina@gmail.com or raise an issue on the GitHub repo.

For updates, star the repo or follow:

https://github.com/mason-larobina/factorio/commits/master.atom